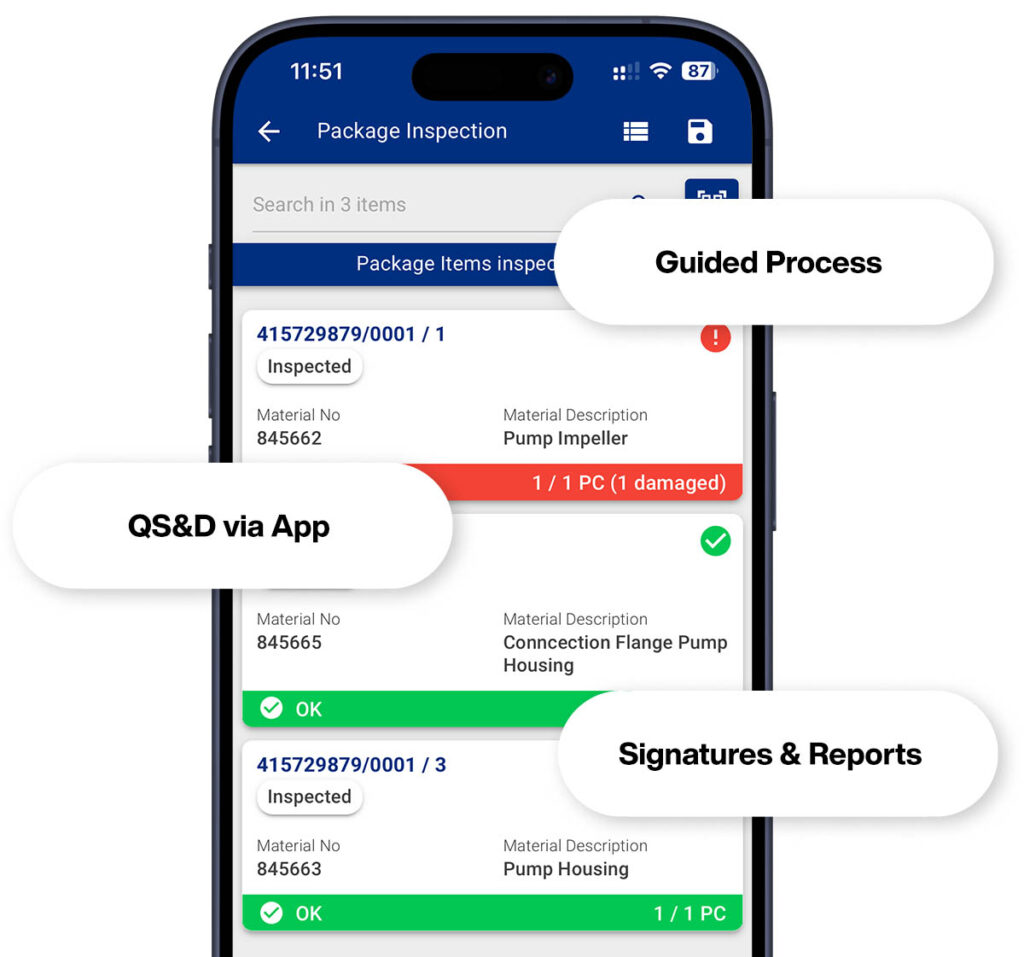

Inspection made easy: Insite LMS guides you through the process of checking and documenting delivered components – and lets you record transport damages right away using the app.

10,000+ Projects On Track

with Insite LMS

OS&D-Management

via App

The “Overage, Shortage & Damage” (OS&D) management of Insite LMS ensures that transport damage and material issues can be resolved quickly.

Capture deviations on the spot during inspection – and create, sign, and send reports directly from your smartphone.

This way, you minimize the risk of project delays and cost overruns.

Paperless processing

All package data digitally at your fingertips

Overview of inspection status

What was inspected and what was not?

Create deviations in the field

Direct link to packages

Comprehensive documentation

Add images and videos

I can only say: Digitize. The earlier, the better. It saves time and resources.

Heinz Pichler

Vice President Global Site Operations

ANDRITZ Hydro

plan.

grow by

plan!

Material inspection and OS&D with Insite LMS

Quickly resolve material issues with efficient OS&D management in Insite LMS.

Simple, paperless handling

- Fully digital inspection process via app

- Scan QR codes on the packing list

- Have all delivery data at hand – including expected items and quantities

Inspection status at a glance

- Know project-wide what has been inspected – and what hasn’t

- All data in one system

Package inspection via app

- Record counted and damaged quantities

- Automatically compare actual quantities with pre-filled packed quantities

- Inspection status is set automatically (OK, overdelivery, underdelivery, deviation, etc.)

- Add comments to the inspection

- Sign digitally

OS&D management

- Document overage, shortage and damage per app

- Directly capture discrepancies

- Overview of OS&D status of all packages

Handle deviations

- Directly capture transport damage and quantity deviations

- Automatically link deviations to packages and package positions

- Comprehensively document issues (photos, descriptions)

- Track deviations by status and responsibility

Digital reporting

- Directly on your smartphone

- Create reports

- Sign reports

- Send reports by email

- Forward reports to the relevant departments

Offline capability

- Work on a project offline

- All information offline “in your pocket”

- Synchronization of changes as soon as online access

All data under control

- All information in one system

- global, role-based access

- easy distribution of deviations

- dashboards for inspection status, open deviations and many more

- high data security – European data centers

SIMPLE.POWERFUL.

Insite LMS takes your projects to a whole new level.

Satisfied users

App developed by practitioners

Real-time information at the touch of a button

Always up to date

Material tracking

From shipping to installation

Material inspection

Digital material inspection with Insite LMS

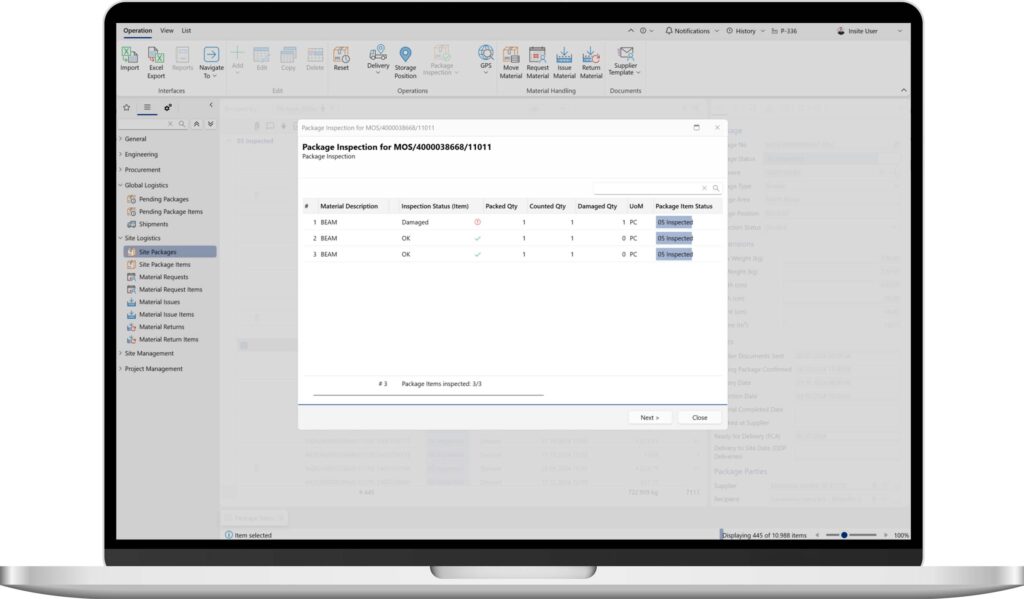

Material inspection via Office solutions

Efficient, integrated OS&D management

Up-to-date delivery data via QR codes on packing lists

Guided package inspection via app

Create deviations directly and link them to packages

Easily create, sign, and share reports via smartphone

Stored in one place – and available to the entire project team

High data security thanks to European cloud solution

Let's talk!

Pick a time that works for you and get your questions answered—no strings attached. Our experts will walk you through Insite LMS and what it can do for you.

Digital material inspection can be that easy!

Material inspections in industrial construction are typically carried out upon delivery, upon storage, upon a transfer of responsibility (e.g. to installation or to the customer) or repeatedly (e.g. for inventory purposes).

At any point in time, Insite LMS ensures that your material inspections follow a consistent process – with every step handled directly in the app.

To know what is supposed to be included in a delivery of materials, you scan the QR code on the packing list on the package with your smartphone. Insite LMS then displays all relevant information about the delivery (details about the package and package items).

As soon as you want to inspect material (for example, when putting it into storage), you start the dialog via the “Package Inspection” item. After entering the actual quantities contained and documenting the components, deviations can be recorded if necessary. All deviations can be assigned and tracked. The system always keeps you informed about what is open and who is responsible.

Best of all, it’s all paperless and without countless Excel files or emails.

OS&D Management – What is it?

OS&D stands for “Overage, Shortage & Damage” and, in the context of industrial construction, refers to the recording and management of quantity variances or damage to material deliveries to construction sites.

Overage

This means that more was delivered than originally ordered.

Shortage

This means that less material has been delivered than ordered, which can lead to delays or problems in site progress.

Damage

This indicates that components arrived damaged or could not be used.

In industrial construction, timely material supply is crucial. Delayed delivery or damage to critical components can significantly affect the construction process. Therefore, OS&D is usually documented and managed as part of a materials management system to immediately identify deviations and initiate countermeasures. Effective OS&D management with Insite LMS helps to minimize cost overruns and project delays by quickly identifying and addressing material issues.

In Site

Why major EPC companies rely on OS&D management with Insite LMS

As a material management system, Insite LMS offers all the functions you need for end-to-end, digital OS&D management in plant engineering.

Increased efficiency

Insite LMS makes material inspections and any deviations easy to handle.

Transparency

Inspection status and deviations can be tracked throughout the project at any time.

Track critical components at all times

The system provides full transparency on deliveries and the status of all components.

Conclusion

As a software solution for digital material inspections, Insite LMS enables a fully digital, end-to-end process. Material issues can be identified immediately, and corrective actions initiated without delay. All data is always up to date, complete, and readily accessible. This site logistics system clearly saves valuable time, reduces the risk of errors, and supports an efficient material flow – from delivery to installation.

A new dimension in industrial construction

Insite LMS goes beyond material inspection and OS&D management – it covers the full range of requirements in industrial plant construction. The platform is made up of numerous seamlessly integrated modules, all specifically designed for the needs of industrial construction projects. This allows you to manage even complex projects in the best possible way – without unnecessary friction. Industrial construction, redefined.

Hands-on guide:

How to digitize industrial construction

Making digital transformation easy: successful software adoption in industrial construction.