Buildability analysis for materials in industrial construction

Maximize planning reliability and material efficiency in industrial construction. With Insite LMS constructability analyses, you know instantly whether, for example, specific pipelines can be installed at a given point in the project.

10,000+ Projects On Track

with Insite LMS

Check buildability – bulk material and the like under control

What can be built with which material and when? Optimize the installation in industrial construction. For projects in which the same components (pipes, flanges, valves, screws and gaskets, etc.) are repeatedly installed, you can use the Insite LMS buildability check to determine which sections can be built and when. In doing so, material in the warehouse and in the delivery process can be taken into account.

This way, you can ideally deploy resources and avoid downtime.

Maximize planning certainty

Avoiding bottlenecks and delays

Material number as a key

Across all project phases, from engineering to assembly

Optimized installation planning

Consider inventory levels and incoming materials

With Insite LMS, we always know what materials are incoming, what’s in stock, and what can be built at any given time – thanks to constructability analyses.

Markus Mook

Head of Construction Materials

thyssenkrupp Uhde Gmbh

Going.

Keep it

Growing!

Feasibility analysis software for material planning

With Insite LMS, you can carry out reliable constructability analyses in industrial construction – especially for piping projects.

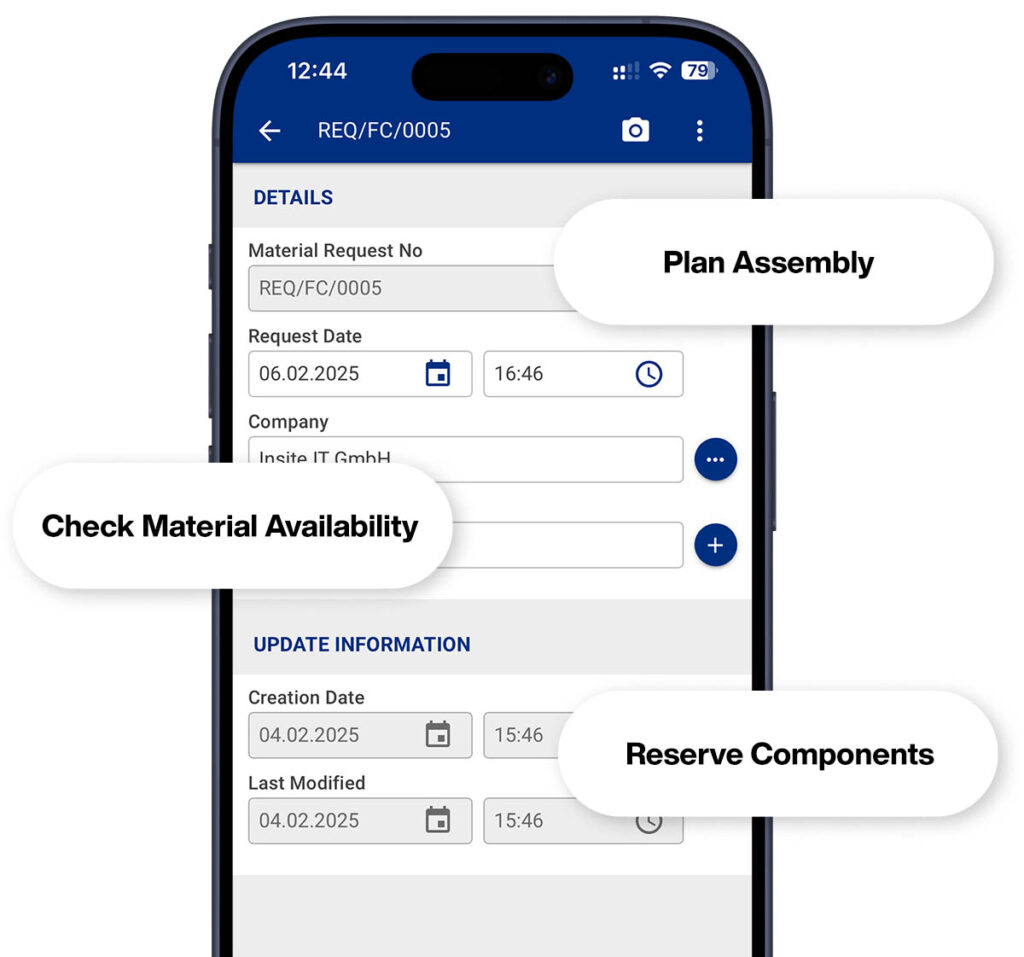

Check buildability

- Isometrics, piping, select plant area

- Installation planning – select date

- Get feedback on material availability

Reserve material

- Reserve required material for installation

- This material will no longer be available for further analysis.

- Create picking lists

End-to-end material tracking

- Material number as the central identifier across all phases

- Detailed quantity tracking: planned, ordered, and shipped

Integration with other Insite LMS modules

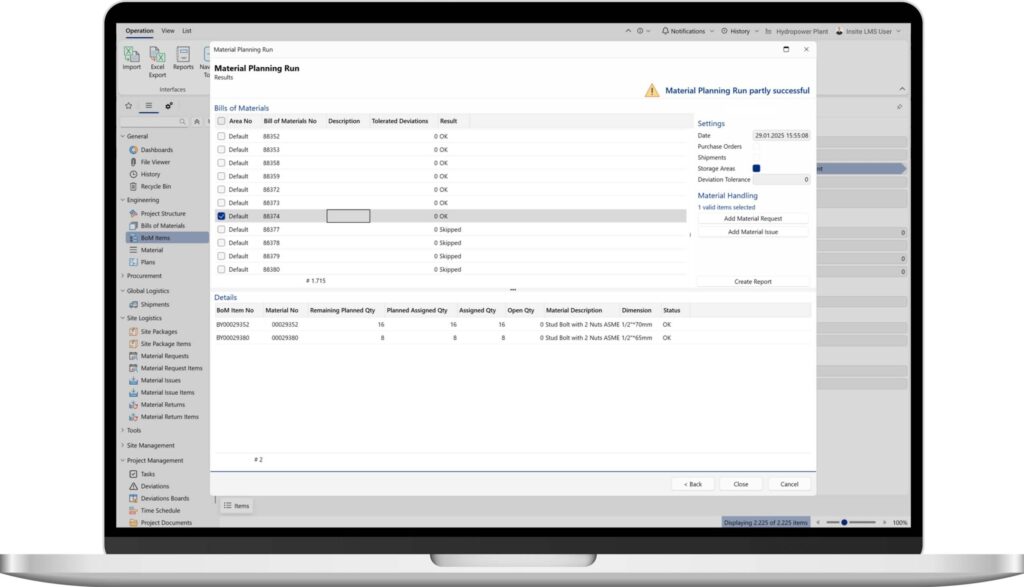

The buildability check takes into account data from many other modules:

- Engineering (BOMs)

- Purchase Orders

- Delivery data

- Packing list information

- Material handling

SIMPLE.POWERFUL.

Insite LMS takes your projects to a whole new level.

Real-time information at the push of a button

Always up to date

Material tracking

End-to-end from shipping to installation

Successful worldwide

20,000+ users, 10,000+ projects

Digital buildability testing

Buildability analyses with Insite LMS

Feasibility studies for Office solutions

Manage bulk material

Carry out the installation planning for specific deadlines

Transparent material information from order to installation

Reservation for future call-offs

High data security thanks to European cloud solution

EXPERIENCE INSITE LMS IN ACTION

In your personal demo, discover how to make your projects more efficient and drive sustainable growth.

Florian Stiefler

Key Account Manager

Reliable constructability analyses in industrial construction

Material availability is crucial for the success of a project in industrial construction. The buildability analyses from Insite LMS provide transparency at the push of a button: those responsible can immediately see whether the required material is available for certain planned construction phases.

What is taken into account in the buildability check of Insite LMS?

Buildability analyses in Insite LMS take into account both the material side and the specific demand side: Which components are available and when? Which construction phase, which pipeline can be built at a certain point in time with the material that is then available?

The buildability analyses of the Insite LMS platform not only check the current material availability, but also determine whether future deliveries will improve buildability.

Site managers and project managers can use this knowledge to make informed decisions and efficiently control the construction process.

How is a buildability analysis carried out?

The planned assembly date is specified in a so-called material planning run and it is determined which materials should be taken into account: material that has been put into storage, is in transit or has already been ordered.

Based on this data, Insite LMS calculates whether the construction project can be implemented with the available materials. In addition, the necessary materials can be reserved directly in the system. This ensures that the required material is actually available for the planned installation and is not used up by other construction phases.

Transparent material tracking – from order to installation

Insite LMS ensures end-to-end material tracking from the order to the warehouse inventory to installation. The material number serves as an identifier that is used throughout all phases – from engineering to ordering and packaging to installation.

The material can thus be tracked seamlessly and transparently in a system that ideally covers the needs of the construction site. In this way, Insite LMS optimizes the use of materials on the construction site and helps to minimize delays.

plan.

row by

plan!

Conclusion

Using Insite LMS as a software solution for buildability analysis e.g. in piping construction significantly simplifies installation planning. At the same time, this approach helps minimize downtime.

A new dimension in industrial construction

Insite LMS doesn’t just solve constructability challenges in industrial construction – it covers all your on-site project needs. The platform is made up of numerous seamlessly integrated modules, each tailored specifically to the requirements of industrial plant projects. This enables you to execute complex projects in the best possible way – without avoidable disruptions. Industrial construction, redefined.

Hands-on guide:

How to digitize industrial construction

Making digital transformation easy: successful software adoption in industrial construction.