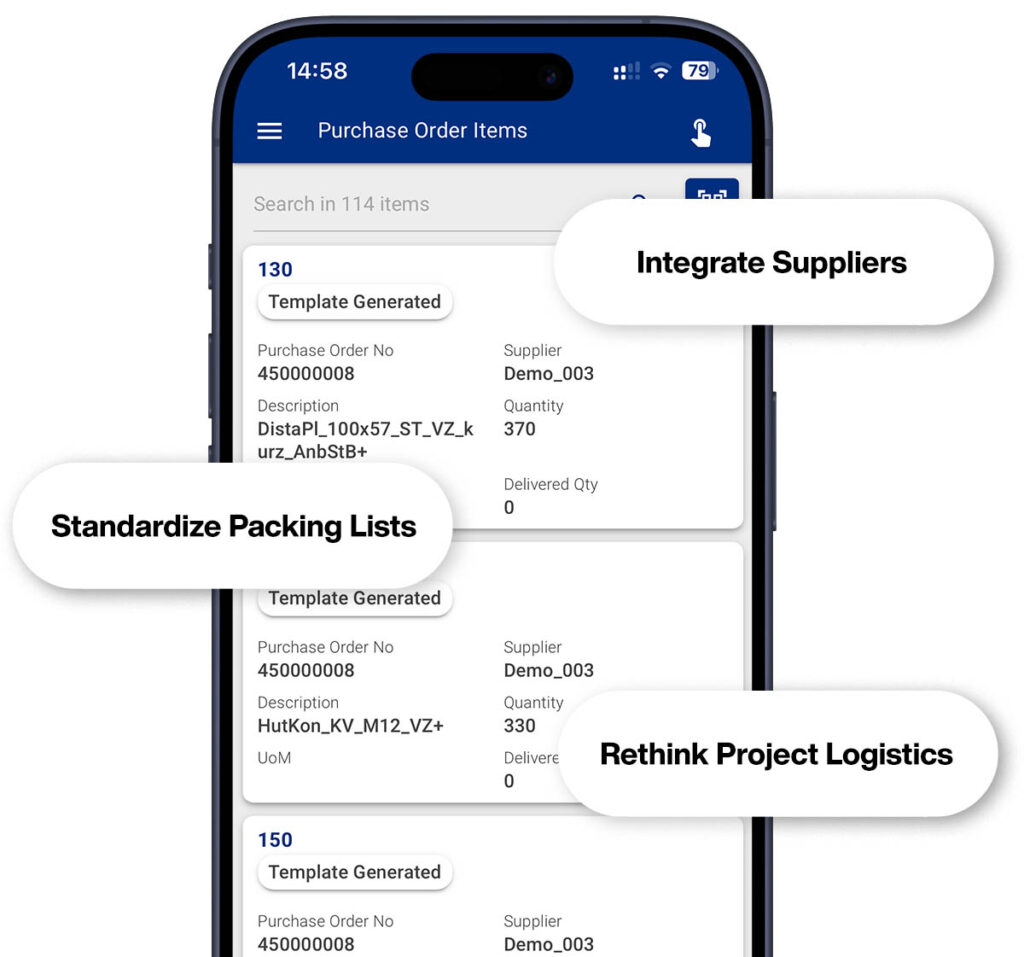

Direct supplier process with standardized packing lists

Absolutely simple! The Insite LMS direct supplier process enables suppliers worldwide to register their deliveries and use standardized packing lists across projects. In addition, all data is available in one system to enable optimal control of the material flow.

10,000+ Projects On Track

with Insite LMS

Digital packing lists

In international projects, the Insite LMS Direct Supplier Process facilitates the coordination of hundreds of suppliers worldwide.

Suppliers simply register their material via an Excel file and an email interface. This ensures uniform, digital delivery and material data in one system.

Insite LMS creates standardized packing lists, customs documents and QR codes for efficient data handling along the entire transport route.

Benefit from project-wide standardized packing lists for all your deliveries worldwide, with all data digitally available and centrally managed.

Simple material registration

by suppliers worldwide

Customized templates

depending on the project and customer requirements

Automatic fault detection

with a completeness check

Transport documents at the push of a button

Standardized packing lists, custom invoices, etc.

Direct deliveries

easily managed

A REAL GAME CHANGER FOR YOUR PROJECT LOGISTICS: DIGITAL, UNIFIED PACKING LISTS AT THE TOUCH OF A BUTTON.

INSITE LMS

The Platform for Industrial Construciton Sites

Plan

Grow By

Plan

Supplier management

with Insite LMS

The Insite LMS Direct Supplier Process is as simple as it is practical: it provides you with standardized packing lists and up-to-date digital material data in one system.

Customized Excel templates

- freely configurable

- reflecting customer and project requirements

- by e-mail to suppliers

Registering deliveries

- no Insite LMS user or password required

- data entry by suppliers

- in Excel templates

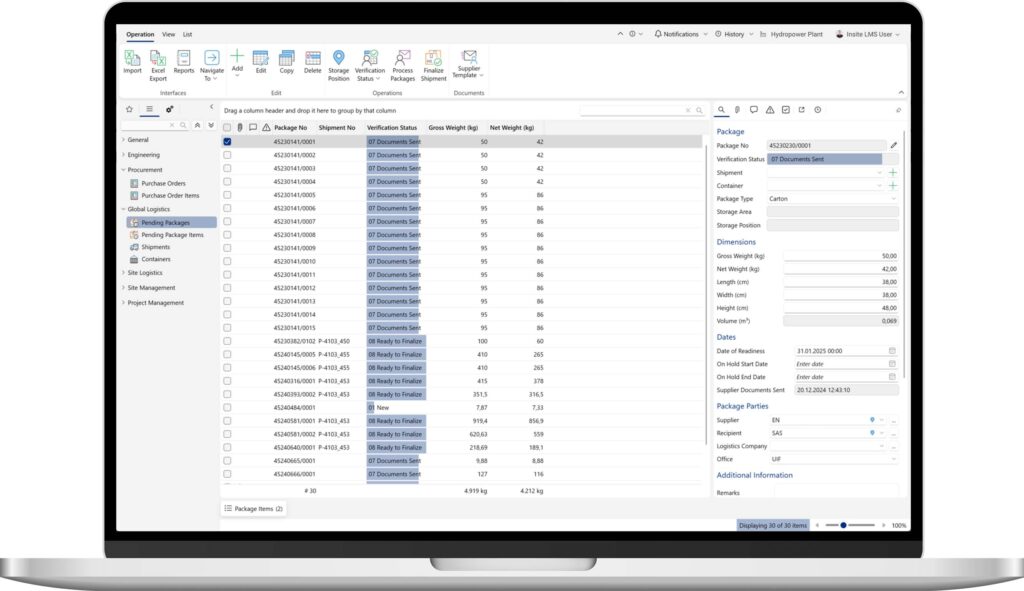

Direct data import into Insite LMS

- via e-mail interface

- automatic error detection and completeness check for error-free submissions

- automatic creation of packages in Insite LMS

Digital packing lists

- automatic creation of packing lists, custom invoices, etc.

- consistent appearance throughout the entire project

- customized design

Labeling

- standardized transport documents

- with QR code (delivery data can be accessed by scanning)

- automatic transmission to suppliers

Optimized control of material deliveries

- knowing delivery dates early

- digital packing list information in one system

- consolidation of packages into containers and shipments

- planning of shipments and deliveries to the construction site

- stay on top of shipments, goods receipt, storage, handovers and inspections

SIMPLE.POWERFUL.

Insite LMS takes your projects to a whole new level.

Global collaboration

Across company boundaries

Projects under control

Timely, compliant and economical construction

Flexibility

Adaptable for different projects

Digitized packing lists

Digital supplier management with Insite LMS

Supplier management via office solutions

Easy material registration by suppliers

Standardized transport documents at the push of a button

Automatic transmission of packing lists to suppliers

Packing list information at your fingertips – with handy QR codes

Seamless material tracking

Efficiently processing route orders

Automated reports at the push of a button

Practical dashboards with real-time information

High data security thanks to European cloud solution

Let's talk!

Pick a time that works for you and get your questions answered—no strings attached. Our experts will walk you through Insite LMS and what it can do for you.

What are the challenges of supplier management in industrial construction?

In industrial construction, hundreds of suppliers worldwide may work on a single project. Without a central digital solution, coordinating, documenting, and tracking these deliveries can be very time-consuming and resource-intensive.

A digital platform makes supplier management much easier and reduces unnecessary effort.

Here are the biggest challenges in supplier management in industrial construction:

1. Coordination of a large number of suppliers

- Challenge: Plant engineering projects often involve hundreds of suppliers worldwide. Coordinating them is complex. A delay at one supplier can impact the entire project.

- Current practice without a suitable digital solution: Many companies use ERP systems to manage suppliers and delivery dates. However, the ERP ends at the factory gate! Communication often takes place via e-mail, Excel files and phone calls, which can lead to discrepancies and misunderstandings.

2. Packing list management

- Challenge: Each supplier uses their own format for packing lists and transport documents. The lack of standardization leads to additional work in checking and tracking deliveries, especially for international projects, which often have special customs and transport requirements.

- Usual practice without a suitable digital solution: Packing lists are often created in Excel and sent as PDFs by email (and thus cannot be processed further). Some companies create packing list templates that are distributed to suppliers, but these are not always standardized and are often processed manually, which is prone to errors.

3. Data quality and completeness

- Challenge: Incomplete or inaccurate information in packing list data can cause delays. Missing or incorrect information (e.g. on material type, quantity or packaging details) can lead to problems with logistics and customs requirements.

- Current practice without a suitable digital solution: Data is often checked manually, especially when packing lists and delivery documents are submitted in different formats. Some companies rely on spot checks or have logistics staff check data for completeness, which can be very time-consuming.

4. Tracking of material flow

- Challenge: Keeping an eye on the entire supply chain – from ordering to shipping to delivery and installation at the construction site – is crucial to avoid bottlenecks. Without transparency, it is difficult to plan!

- Common practice without a suitable digital solution: Many companies rely on obtaining shipping information via email or tracking deliveries using proof of delivery. More modern solutions integrate tracking information into ERP systems, but ERP systems often end at the factory gate and are not designed for international project logistics in industrial construction. With Insite LMS, tracking starts where your ERP ends.

5. Communication and documentation

- Challenge: Communicating with numerous suppliers and managing delivery documents is time-consuming. Without a central system that combines all the information, documents such as packing lists and shipping information are often scattered and difficult to find.

- Common practice without a suitable digital solution: Supplier management and communication often take place via email, telephone and in Excel. Documents are stored in email inboxes and various folders, resulting in an unstructured flow of information and increased administrative work. Some companies use SharePoint or similar platforms to store documents centrally, but this is not a complete solution for supplier management.

How to make supplier management in industrial construction efficient

Insite LMS makes supplier management in industrial construction digital and efficient. The effort for manual activities, controls and coordination is significantly reduced.

The process does not require any special software or dedicated Insite LMS users for suppliers! This ensures that service providers worldwide can be easily integrated.

Suppliers register deliveries in advance: They fill out delivery and material data in an Excel document and send the document by e-mail to Insite LMS. The Excel document can be structured and designed according to project and customer requirements.

In the next step, Insite LMS automatically and standardizedly creates all necessary transport documents and packing lists. The packing lists contain QR codes that allow quick retrieval of the delivery data.

Finally standardized data

The Insite LMS direct supplier process ensures that packing lists from suppliers worldwide contain standardized and quickly retrievable information – and that all data is digitally available in one system. The multiple editing, checking, managing and distributing of umpteen Excel files is no longer necessary, and the project logistics are significantly relieved.

plan.

row by

plan!

Why global players in industrial construction rely on the direct supplier process of Insite LMS

The convenience offered by the Insite LMS direct supplier process is appreciated worldwide. The result: standardized packing lists with practical QR codes and clean delivery and material data in one system.

High data quality

The standardized material registration by suppliers lays the foundation for consistent, transparent material control through to installation. Packing list information, delivery data and material information are centrally available in digital form, and the construction site can continue to work directly with the data from the project logistics.

Standardized packing lists

All deliveries for a project have standardized transport documents and labeling.

Practical handling

QR codes on the packing lists provide direct access to all packing list information via an app.

Conclusion

is ingeniously simple – thanks to the Insite LMS Direct Supplier Process. Hundreds of suppliers worldwide can be integrated without additional effort, and packing list information is available digitally in ONE system.

A new dimension in industrial construction

With Insite LMS, you take you projects to the next level. The platform consists of numerous modules that work together seamlessly – tailor-made for the industrial construction sector. This allows you to manage complex projects in the best possible way – without unnecessary friction.

Hands-on guide:

How to digitize industrial construction

Making digital transformation easy: successful software adoption in industrial construction.