A new dimension in construction site logistics software

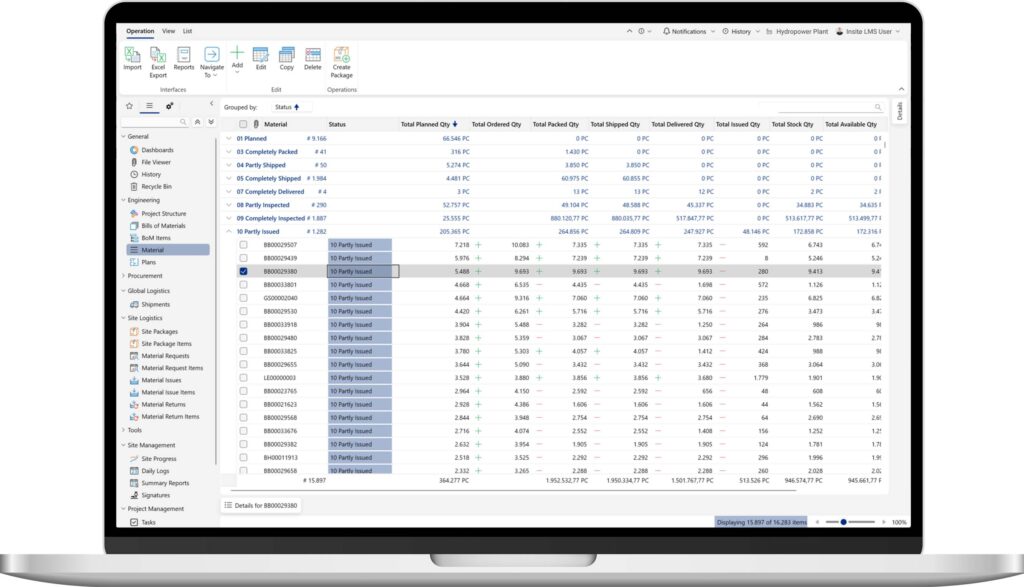

Material control via software instead of logistics via Excel!

Take material logistics on your construction sites to a whole new level! With Insite LMS, you know in advance what is coming and when, and you can process incoming goods digitally. You can optimally manage storage locations and material withdrawals and benefit from digital reporting.

10,000+ Projects On Track

with Insite LMS

All the ways Insite LMS empowers your projects

Insite LMS is the leading solution for managing construction sites. The platform seamlessly integrates project logistics, materials and site management.

Supply chain management with Insite LMS

The platform enables the control of complex supply chains and ensures that deliveries to the construction site can be perfectly coordinated and processed. Benefit from a wide range of modules that work together seamlessly.

Site logistics with Insite LMS

Insite LMS is the leading software for digital construction site logistics in industrial plant construction. Benefit from a wide range of modules that work together seamlessly. The solution is valued by site logisticians because it minimizes the risk of delays and material bottlenecks.

You can also benefit from the buildability analysis that Insite LMS offers. This is particularly useful in pipeline construction to determine what can be built when with the material that is then available.

Site management with Insite LMS

Insite LMS is the leading software for digital site management in industrial construction. Benefit from a wide range of modules that work together seamlessly.

Manage site human resources with Insite LMS

Insite LMS is the leading software for managing construction sites and site resources. The solution is valued by those in charge because it is practical and offers exactly what is needed for successful project execution. Benefit from a wide range of modules that work together seamlessly.

Project management with Insite LMS

The platform includes practical project management features tailored to real-world needs. Project leaders value the solution for its hands-on usability and the precise functionality required for confident project control. Benefit from a wide range of seamlessly integrated modules.

Digital solutions for optimized logistics processes on your construction sites

In industrial construction, site logistics is a central challenge that can determine the success or failure of a project. Those who digitalize this area in a meaningful way will be clearly ahead. With Insite LMS, you can manage materials and resources digitally and efficiently from shipping to installation.

Insite LMS optimizes site logistics in your projects.

Material tracking

consistently and in a centralized system

Digital processing of incoming goods

via app on smartphone

Storage area management (with GPS)

digitally structure interior and exterior surfaces

Transport damage documentation

including deviation management

We use Insite LMS in our projects primarily for materials management and for feasibility and buildability studies.

Markus Mook

Head of Construction Materials

thyssenkrupp Uhde GmbH

On Site

Digital construction site logistics

Say goodbye to opaque processes and benefit from a digital solution that covers the material flow from dispatch to installation.

construction site management with Insite LMS

construction site management via office solutions

Customized for industrial construction

Efficient and time-saving

Consolidated, centrally available data for all project participants

Easy handling

Reports at the touch of a button

High data security thanks to European cloud solution

Offline capability incl. automatic synchronization

Practical dashboards

Let's talk!

Pick a time that works for you and get your questions answered—no strings attached. Our experts will walk you through Insite LMS and what it can do for you.

What is the aim of construction site logistics in plant construction?

Obviously, the aim is to control the flow of materials as well as assembly and installation so that projects can be completed on time and within budget.

What are the typical challenges of materials management on construction sites?

In projects, you are confronted with challenges such as material bottlenecks, delays and coordination problems. If certain components are not delivered on time or are defective when they are delivered, if material is lost or it is unclear where exactly what can be found, downtime, additional work and frustration are inevitable.

How does it work without site logistics software?

Without the right software, site logistics managers are forced to take alternative approaches. Not infrequently, this means working from an office, i.e. with countless, distributed Excel spreadsheets, e-mails and files and storage locations.

In this case, material management is complicated by opaque information, countless data sources and inefficient communication.

This way of working leads to avoidable disadvantages and delays in site logistics.

Disadvantages of building without construction site logistics software

Unclear material availability

Without a reliable overview of order status, material in flow and current stock levels, it is impossible to make informed decisions.

Manual effort and susceptibility to errors

Since material deliveries and construction site logistics are not handled digitally across the board withonesystem, information has to be entered, processed and checked multiple times.

Coordination problems

Communication gaps, media disruptions (i.e. interruptions in communication due to different systems) and unequal levels of information between logistics, suppliers and site management make collaboration more difficult.

Material losses

Inadequate tracking can lead to losses and repeat orders.

The solution? Material control via software instead of logistics via Excel!

Insite LMS was developed specifically for the requirements of industrial construction as a site logistics solution. This means that Insite LMS can handle site logistics at all levels – and all without the countless Excel files that still often dominate site logistics today.

The solution provides the responsible persons with a complete overview of material flow, stock levels and the status of installation and assembly! They control and monitor all material movements, have an up-to-date overview of all stock levels and efficiently manage suppliers and orders. Thanks to interfaces to ERP systems such as SAP S/4HANA, Microsoft Dynamics 365, Oracle ERP Cloud and AMS ERP, all systems remain synchronized. This is how construction site processes become efficient and transparent.

Optimal flow: digital material management on the construction site

Insite LMS scores highly with project logistics and construction site logistics companies thanks to its reliable and consistent material management: material inflow, delivery, inspections, storage location management and material issue for installation/assembly are all handled digitally in one system. The software can also be used to directly record and manage delivery documentation, any material defects and deviations.

This can all be done conveniently in the field using an app on smartphones or tablets and in the back offices on laptops and computers.

Advantages of digital construction site logistics with Insite LMS

This software for materials management and site logistics offers everything you need for successful project execution in industrial construction. Use it to network project logistics, site managers and suppliers on a central platform.

End-to-end digital material tracking and management

Know what is coming and when, even before it is delivered to the construction site. Plan acceptance, manage storage locations and document transport damage directly via the app.

Optimized material availability

Benefit from reliable, up-to-date material data in one system. Monitor and control all material-related processes in real time. Avoid bottlenecks and keep your projects on track.

Resource conservation and cost reduction

Digital site logistics minimize material losses and downtime. This saves you time and money.

Clarity and faster decision-making

Material information is available in one system at the push of a button. Inventory levels are transparent. This real-time information enables informed decision-making and accelerates project progress.

Error-free processes

The site logistics software Insite LMS supports clear, transparent processes. Handling materials management digitally from end to end using this software significantly reduces potential sources of error.

Sophisticated construction site logistics software for perfect control of the material flow on the construction site.

Insite LMS

The Platform for Industrial Construction Sites

Construction site logistics via Insite LMS

Material Management with Insite LMS stands for optimized material flow and digital efficiency: from paperless material acceptance, inspections, transport damage documentation and deviation management to real-time inventory management. Functions such as storage, transfer, reservation, material issue and return are easily controlled via an app. Design for manufacturability checks ensure smooth processes, while ERP integration and transparent communication ensure seamless traceability and optimal collaboration.

All packing lists in one system

Whether in-house production or direct deliveries from your suppliers, the quality of your packing lists determines the quality of your construction site logistics.

Material tracking in real time

Track material movements seamlessly and accurately.

Automated inventory management

Stock quantities are updated automatically, minimizing sources of error.

Better communication

All project participants have access to a central platform with up-to-date data.

Proactive planning

All information on orders, deliveries and material availability is available at the touch of a button. This makes it possible to deploy resources in such a way that downtimes are avoided.

Insite LMS at a glance

Conclusion

Hands-on guide:

How to digitize industrial construction

Making digital transformation easy: successful software adoption in industrial construction.