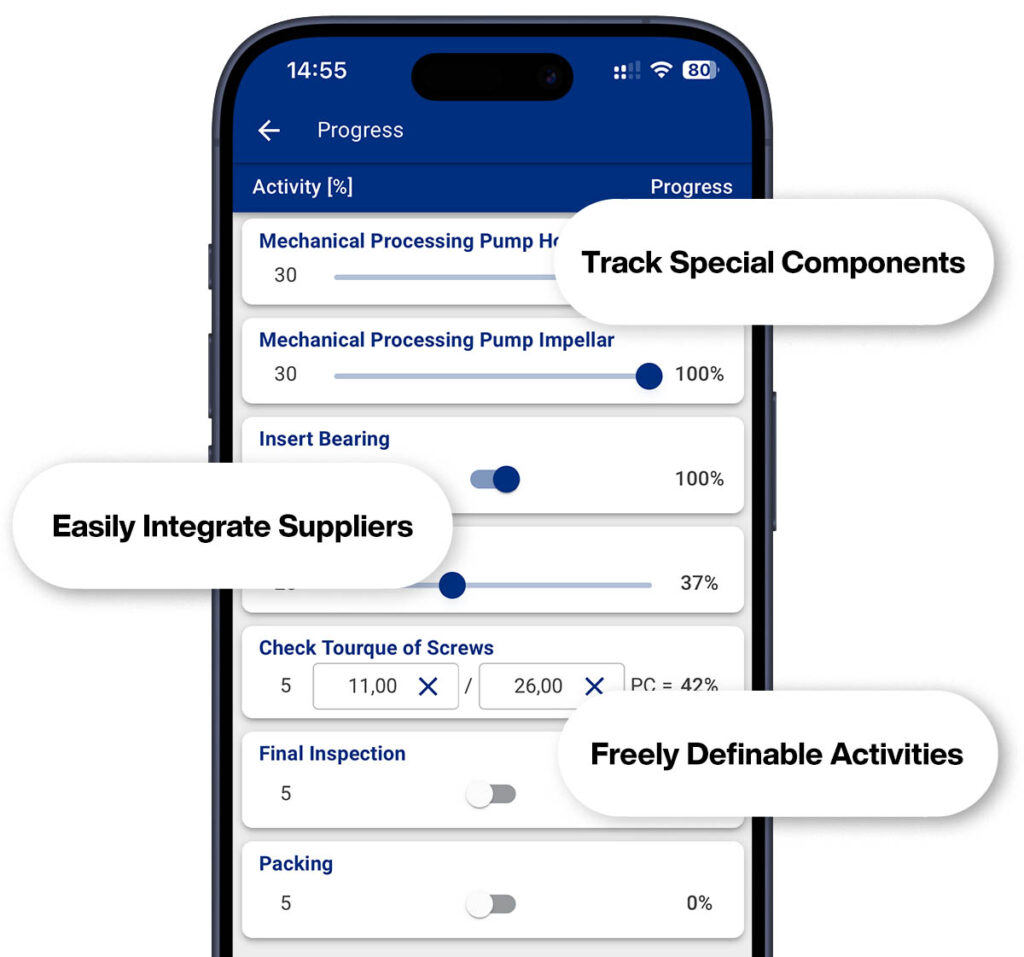

Digital manufacturing tracking of special components

Standardized progress evaluation tailored for the manufacturing of made-to-engineering parts! Easy supplier integration, clear progress tracking, target-actual comparisons and status reports at the push of a button for transparency and efficiency.

10,000+ Projects On Track

with Insite LMS

Efficient manufacturing monitoring for made-to-engineering-parts

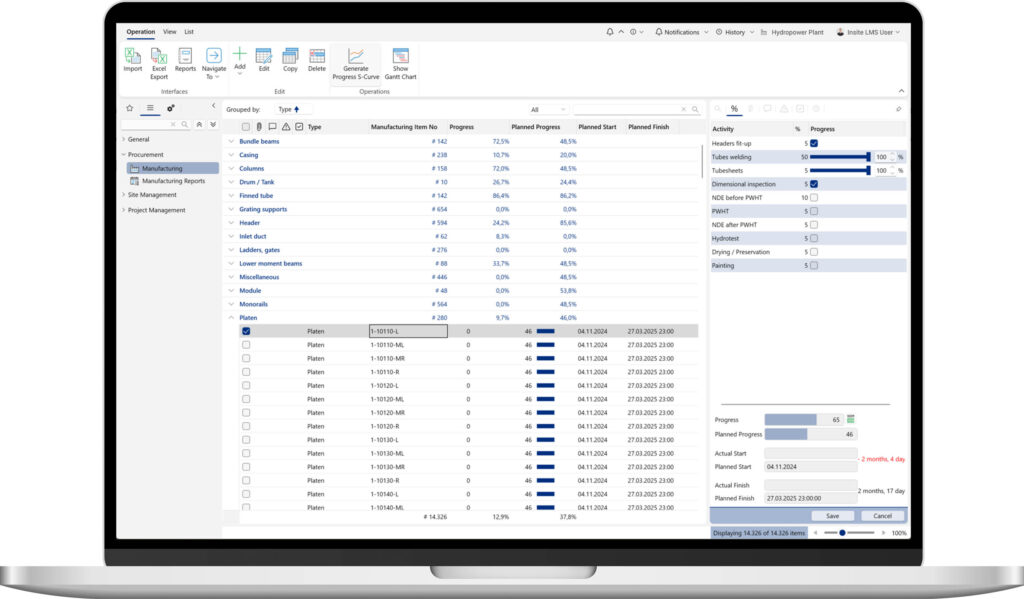

Insite LMS digital status tracking replaces the numerous Excel files that are normally constantly being exchanged between suppliers and clients. How? Manufacturers and suppliers receive limited access to regularly update the manufacturing status of their components. With Insite LMS, you provide user-friendly digital checklists for this purpose, so that the status can be easily recorded and compared project-wide. Reports and dashboards then display the current manufacturing status at the push of a button.

Project-wide standardized status information on all special manufacturing at a glance!

Progress of the manufacturing

tracked by all subcontractors

Manufacturer web portal

for easy supplier integration

Know bottlenecks early on

and react in a targeted manner

Measure supplier performance

Focusing on quality and punctuality

With Insite LMS, you always have control over progress and ensure maximum transparency in the project.

Insite LMS

The Platform For Industrial Construction

Act Big.

Build Big.

Digital manufacturing monitoring

with Insite LMS

With Insite LMS, you always have an overview of the manufacturing of your special components, such as machines and parts.

Supplier web portal

- limited, secure access for manufacturers and suppliers

Real-time information

- all manufacturing status data

- project-wide at the touch of a button

Project-wide standardized status tracking

- regular status updates

- by manufacturers or in-house manufacturing supervisors

- via configurable checklists

- in the mobile app, via Excel or web portal

Additional information

- addition of photographs

- creation of deviations

- addition of attachments

Simple reporting

- iniform reports

- practical templates

- for the entire project

- at the touch of a button

Dashboards

- manufacturing status at a glance

- S-curves for target/actual comparisons

Collaboration tools

- project communication

- task management

- digital signatures

- deadline management

SIMPLE.POWERFUL.

Insite LMS takes your projects to a whole new level.

Practical customizing

Flexibly customizable with minimal effort

Practical dashboards

All information at a glance

Global collaboration

Beyond company boundaries

Digital manufacturing monitoring

Digital manufacturing monitoring with Insite LMS

Manufacturing monitoring using office solutions

Standardized tracking across the project

Standardized, configurable checklists

Easy supplier integration

Standardized status reports at the push of a button

Target/actual comparisons at the touch of a button

All information available in one place

Practical dashboards with real-time information

High data security thanks to European cloud solution

Let's talk!

Pick a time that works for you and get your questions answered—no strings attached. Our experts will walk you through Insite LMS and what it can do for you.

Challenges in the status tracking of made-to-engineering parts in plant engineering

1. Specific requirements

Made-to-engineering parts are manufactured specifically for a project.

2. Long delivery times and risk of delays

Manufacturing these special components can be a lengthy process – delays affect the entire project plan!

3. Quality assurance and documentation

Extensive testing, quality control and documentation are required to meet the requirements.

4. Coordination of multiple suppliers

Since several suppliers are involved, it is difficult to manage the project without up-to-date information at your fingertips.

5. Transparency in progress

It must be possible to transparently track the manufacturing progress in order to identify and counteract delays.

What does manufacturing monitoring look like without a digital solution?

1. Regular status updates and meetings

Frequent status checks, e.g. by email and meetings or phone calls with suppliers to ensure that schedules are being met.

2. Excel lists and manual checklists

Excel lists or other manual systems are used to document progress and identify delays.

3. Various communication channels and e-mail communication

Information is distributed across different platforms and communication channels. This makes traceability more difficult.

Advantages of Insite LMS

1. Centralized real-time progress monitoring

Insite LMS enables digital and transparent progress tracking of all made-to-engineering parts, so delays can be identified and minimized early.

2. Standardized and automated quality checks

The platform offers standardized checklists and automated progress assessments that simplify and accelerate documentation and quality assurance.

3. Seamless supplier integration

Suppliers can be given limited access to project-related information via the Insite LMS web portal, making collaboration more efficient and secure.

4. Status reports at the push of a button

Progress and quality reports can be accessed at any time, which creates transparency and reduces the amount of communication required.

5. Efficient, project-wide standardization

Insite LMS promotes uniform processes and ensures project-wide standardization that simplifies administration and reduces sources of error.

6. Easy handling and secure access

The user-friendliness of the portal makes it easier for everyone involved to use, while also ensuring the protection of sensitive data through limited access.

plan

Grow by

plan

That's why global players in industrial construction rely on Insite Lms manufacturing tracking

Maximum efficiency

Centralized manufacturing tracking and standardized progress assessment ensure consistent data and minimize delays.

Full transparency

All manufacturing data and material movements are seamlessly documented and can be accessed at any time. Real-time reports and dashboards enable precise progress monitoring that highlights bottlenecks at an early stage.

Optimized reporting

Dashboards and status reports at the push of a button show where the project stands. The effort required to create the reports is reduced to a minimum!

Conclusion

With Insite LMS, you can track the manufacturing of special components more efficiently and benefit from significantly easier project management.

A new dimension in industrial construction

Insite LMS not only digitalizes manufacturing tracking: With Insite LMS, you take you projects to the next level. The platform consists of numerous modules that work together seamlessly – tailor-made for the industrial construction sector. This allows you to manage complex projects in the best possible way – without unnecessary friction.

Hands-on guide:

How to digitize industrial construction

Making digital transformation easy: successful software adoption in industrial construction.