Material handling software for industrial construction sites

With Insite LMS, you manage all material movements in a single system – from storage and relocation to the reservation and issuing of components for installation. Benefit from real-time stock information, complete documentation, and clear dashboards.

10,000+ Projects on Track

with Insite LMS

Material Handling at the Highest Level

Handle every step seamlessly and transparently in a central system – with a standardized process for storing and issuing materials.

Insite LMS supports you with practical location management including GPS tracking, real-time warehouse data, and complete documentation, reports, and dashboards.

Material handling software for industrial construction professionals: Receipt, inspection, storage, warehouse management, and issuing – all via app.

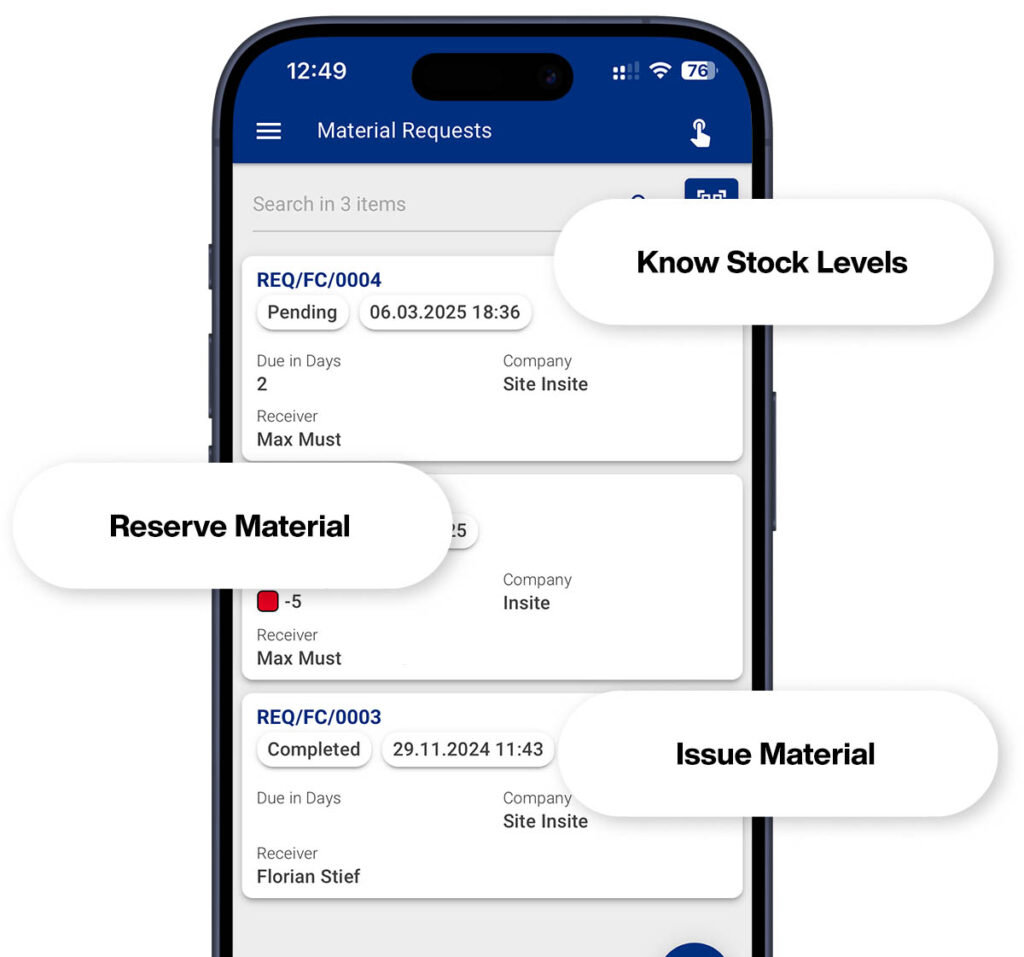

Practical App

Store, relocate, reserve, issue

Digital warehouse Management

Manage and allocate storage locations

Documented material issuing

Complete material history in one system

Insite LMS was indispensable for our major project, the construction of a metro in Riyadh, Saudi Arabia. All material deliveries were digitally recorded, reserved in advance in one of our warehouses and delivered just in time to the respective construction sites, which were spread throughout the city.

Karl Bareth

Logistics Director

Siemens Mobility GmbH

Act big.

Build big.

MATERIAL HANDLING

with Insite LMS

Manage material movements effortlessly – with the Insite LMS app.

Store Material

- Assign storage locations

- Record GPS position

- Check storage conditions

- Automatic stock level updates

Relocate Material

- Assign storage location

- Record GPS position

- Check storage conditions

- Automatically update stock levels

Reserve Material

- Reserve components for installation and assembly

- Create binding pre-orders

- Receive picking list

Issue Material

- Documented material issue

- Handover protocol

- Automatic stock level updates

Manage Storage Locations incl. GPS Position

- Structure storage areas

- Assign and save storage locations

- Capture GPS position

- Define storage conditions

Complete Material History

- Documented material movements

- Know what was where – and when

Add Deviations

- Capture open points directly as needed

- Assign and process deviations

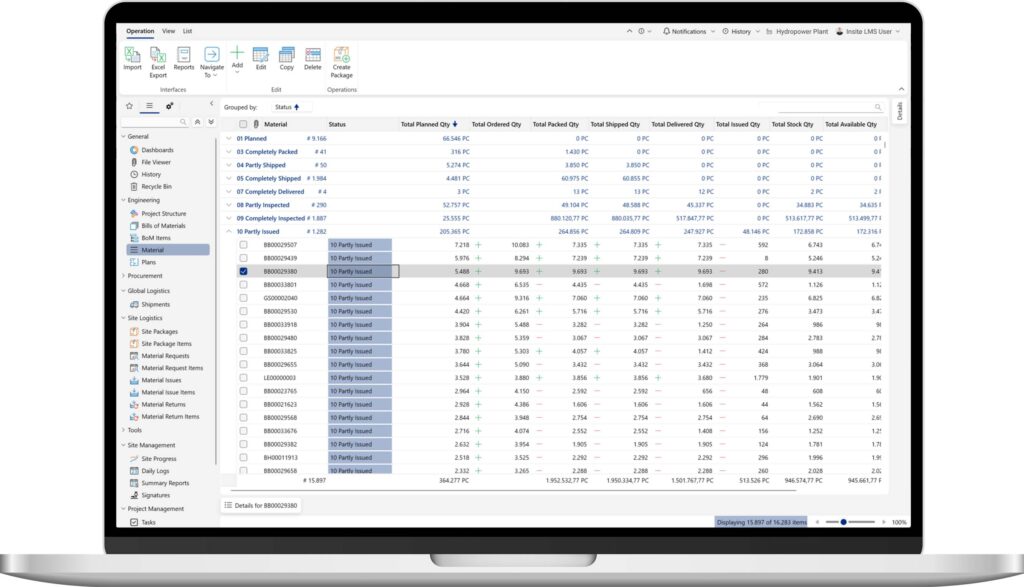

Use Material Data in Reports and Dashboards

- Use current data in reports

- Display material information in dashboards, including target-actual comparisons

Project-wide Collaboration

- Tasks

- Signatures

- Deadlines

SIMPLE.POWERFUL.

Insite LMS takes your projects to a whole new level.

Project efficiency

Time, resources and costs under control

Real-time information at the touch of a button

Always up to date

Material tracking

From shipping to installation

Your direct path to better material handling

Digital material handling with Insite LMS

Material handling via office solutions

Current stock levels at the touch of a button

GPS-based storage location management

Centralized material information readily available to all project stakeholders

Automated material reports at the push of a button

Practical dashboards with real-time information

High data security thanks to European cloud solution

EXPERIENCE INSITE LMS IN ACTION

In your personal demo, discover how to make your projects more efficient and drive sustainable growth.

Florian Stiefler

Key Account Manager

Material Handling with Insite LMS

Industrial construction in a new dimension: Don’t miss these articles.

Challenges in Material Handling on Industrial Construction Sites

In industrial construction, ensuring material availability and managing deviations in a traceable way are the cornerstones of successful project execution.

Knowing where materials are stored and ensuring that storage conditions meet the specific requirements of the components is essential. With custom-made parts, for instance, serious issues can arise if a component cannot be located, has been stored incorrectly, or has been damaged. Such situations can cause significant delays.

Bulk materials and custom-made components in small batch sizes are both part of day-to-day operations. Each type of material must be handled, stored, and issued correctly—right on time for assembly and installation.

However, real-time data or even easily accessible information about where specific materials are located and what quantities are available when is often lacking.

Inefficient communication between teams, inaccurate inventory management, and volatile supply chains further complicate effective material handling. All of this poses major challenges for material managers. Without a consistent, digital solution tailored to site logistics, valuable optimization potential is quite literally left on the table.

How to Streamline Material Handling

Material handling software designed specifically for the demands of industrial construction sites is the most effective way to ensure smooth material flow:

With Insite LMS, you manage all material data and movements seamlessly in one centralized system.

The storage, relocation, reservation, or issuance of mechanical components, pipes and piping materials, structural steel, electrical components, machinery and equipment, insulation and sealing materials, special materials, and automation parts is handled in a structured and fully documented manner.

With Insite LMS, you maintain full visibility of all materials in your project, minimize losses, and handle any damage to components quickly and in a fully documented manner.

The software allows you to structure storage areas according to the specific needs of each project: define storage locations and conditions, assign storage positions, and capture GPS coordinates. This ensures you always know where materials are located – and under what conditions they are being stored.

When components or materials are needed for installation and assembly, they can be reserved in the system and automatically recorded upon withdrawal. This significantly simplifies the coordination and material supply for multiple installation companies or teams. Inventory levels are updated in real time, giving you constant access to up-to-date stock information.

plan.

row by

plan!

I don't even want to imagine how we would have managed this level of complexity without Insite LMS.

Karl Bareth

Logistics Director

Siemens Mobility GmbH

That is why global players in industrial construction rely on material handling from Insite LMS

Inefficient material handling is finally a thing of the past! All processes can be centrally managed, fully documented, and accessed at any time for reports, dashboards, and queries.

Increased Efficiency

Centralized material control optimizes site logistics and minimizes unnecessary waiting times.

Transparency

Material movements are fully documented, preventing losses and bottlenecks.

Reports

Reports and dashboards provide accurate information on material stocks and movements in real time.

Sustainability

Insite LMS optimizes warehouse management and enables proactive material planning – reducing both excess inventory and material waste.

Conclusion

Insite LMS optimizes on-site material management. With this proven material handling solution, you can manage material movements on your construction site efficiently and with full traceability.

A New Dimension in Industrial Construction

Insite LMS goes beyond material handling and warehouse management: it covers all key requirements in industrial construction. The platform is made up of numerous modules that are seamlessly integrated and are purpose-built for industrial construction. This allows you to manage complex projects in the best possible way – without unnecessary friction.

Hands-On Guide:

How to Digitize Industrial Construction

Making digital transformation easy: successful software adoption in industrial construction.