Optimized Processing of Material deliveries to construction sites

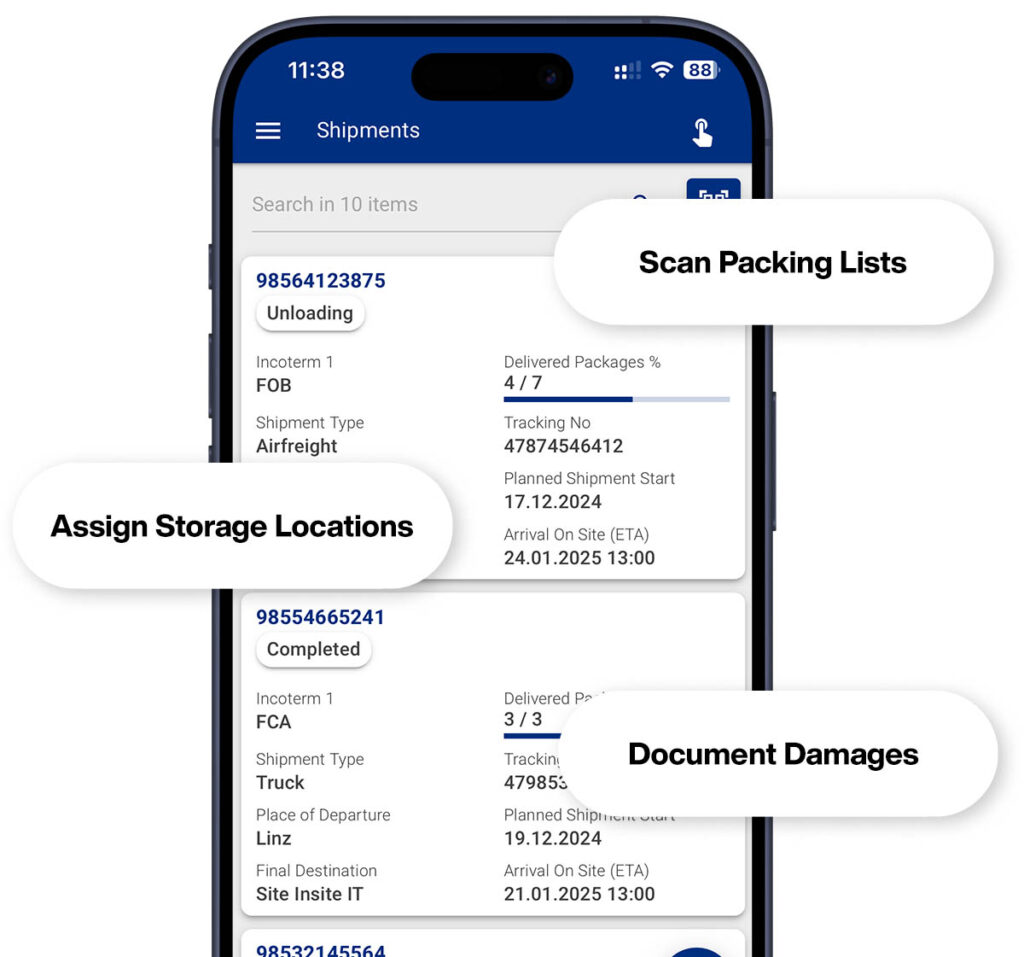

There is no easier way to accept materials in industrial construction. With Insite LMS, you know early on what will be delivered to the construction site and when. When accepting the material, you can scan practical QR codes on the packing lists and seamlessly document packages using the app. You can also manage and assign storage areas and carry out structured inspections. All in one system.

10,000+ Projects On Track

with Insite LMS

Digital goods receipt on the construction site

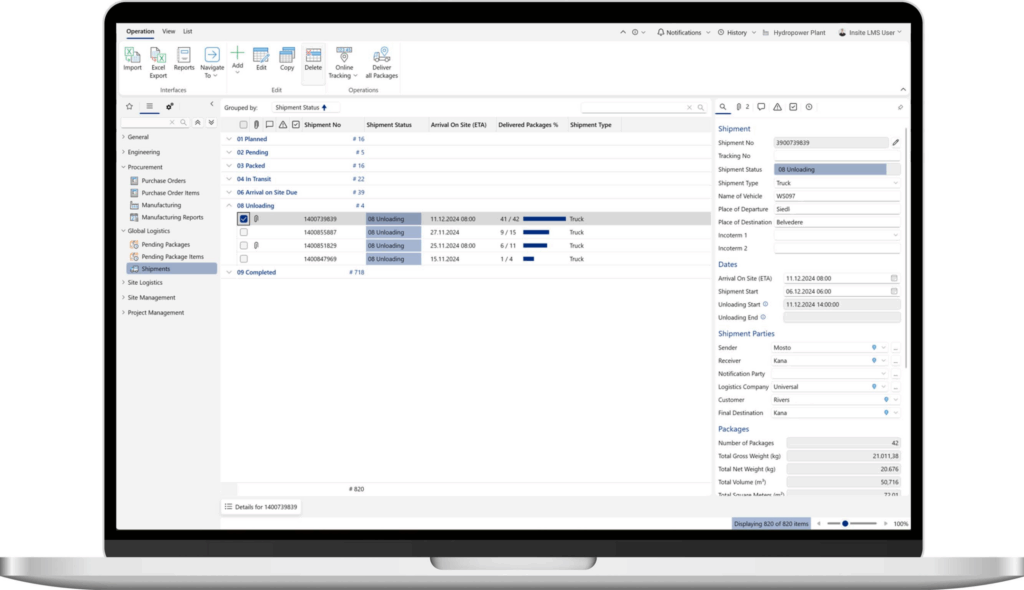

All deliveries preregistered in Insite LMS are recorded on-site by simply scanning the QR code on the packing list. All package information is already available in the system, and the delivery status is updated system-wide upon receipt.

When materials arrive at the construction site, the condition of crates and packaging can be digitally documented immediately (e.g. via photos). Afterwards, controlled inspection, storage, and material withdrawal are carried out using Insite LMS.

Easily scan QR codes

On packing lists using your smartphone

Structure storage areas

Assign and document storage locations

Document packages

Handle transport damage

We benefit from the digitalization of our processes and the associated documentation – and so do our customers.

Mathias Wirth

Site Manager

Voith Hydro

to build

big size

MATERIALS RECEIPT FEATURES AT A GLANCE

All package data is already stored in the system – at the time of delivery, all that’s needed is to scan the QR codes on the packing lists generated by Insite LMS.

Accept deliveries via app

- Scan QR codes on packing list

- All delivery data available digitally in the app

- Digitally document packages (e.g. with photos)

Carry out completeness checks

- Verify delivery completeness (“Are all crates there?”)

- Perform further checks at material level

Document transport damages

- Mobile app

- Add photos, videos, notes, voice recordings and signatures

- Record deviations and forward them to the responsible parties

- Data centrally in the cloud

Package status at a glance

- Packaged

- Shipped

- In customs

- Delivered

- Checked

Manage storage areas

- Organize storage areas

- Assign storage locations

- Capture GPS positions

- Define and assign storage conditions (indoor/outdoor, climate control)

- Ensure that each material is stored correctly: Receive notifications when discrepancies in storage conditions occur between the package and the storage area

Works offline

- Work on a project offline

- All information offline “in your pocket”

- Synchronization of changes as soon as online access

All data under control

- All information in one system

- Global, role-based access

- Dashboards for deliveries, storage, and material flow

- High data security – European data centers

Integration with other Insite LMS modules

- Supply Chain Management

- Deviations

- Reports

- Dashboards

- Buildability analysis

Simple.Powerful.

Insite LMS takes your projects to a whole new level.

One Tool On Site

One app for all on-site processes

Data under control

Central data storage and access control

Streamlined material tracking

From shipping to installation

ON-SITE MATERIAL RECEIPT

Controlled goods receipt with Insite LMS

Goods receipt via Office solutions

Centrally stored package data – accessible to all project stakeholders

Material receipt via QR code scan on the packing list

Standardized packing lists

Simple delivery documentation

Simple storage location management

Simple material inspection

Simple claims handling

Efficient and time-saving

High data security thanks to European cloud solution

Let's talk!

Pick a time that works for you and get your questions answered—no strings attached. Our experts will walk you through Insite LMS and what it can do for you.

Delivery of materials for industrial construction

The delivery and acceptance of materials at the construction site is a critical process that must be well organized and documented. A central task here is the documentation of the packages upon delivery. Ideally, the incoming material is digitally registered and assigned to a storage location immediately upon delivery. Otherwise, it can be difficult to claim for transport damage afterwards. In addition, valuable time is lost searching for material in case of doubt. In the worst case, material cannot be found and has to be reordered. In industrial construction, this means that downtime is risked.

Checking incoming goods at the construction site does not have to be complicated.

Those who use Insite LMS for supply chain management know at an early stage which material deliveries can be expected and when. This means that unloading equipment and personnel can be scheduled in good time. In addition, all data for the deliveries and packages is already available in digital form in the system.

QR codes on the packing lists that Insite LMS has generated for the suppliers enable the rapid processing of material deliveries to the construction site: when unloading, all that needs to be done is to scan the QR code using an app and all the data is available.

Documentation of the acceptance of packages

When the delivery arrives, all the contents of the boxes, etc. can be digitally documented. This is also done in the app on the smartphone.

This provides all project participants with centralized and traceable information on the status of the delivery when it arrives at the construction site.

Possible damages or wrong deliveries (shortages, missing parts) can be asserted immediately. Damage in transit is documented directly on the go, typically during the inspection of the delivery. All of this contributes significantly to efficient and transparent material delivery and acceptance.

Storage bin management

An important step in advance is the structuring of storage areas on the construction site. This can be easily done with the construction site logistics software Insite LMS. In the system, you can define and structure storage areas. In addition, storage conditions can be defined for different requirements (e.g. indoor and outdoor areas, air-conditioned storage areas). This ensures that incoming material is stored under the right conditions. If a package is stored in an unsuitable location, the system will issue a corresponding message.

When storing, you save the information about the storage locations including the GPS position for all packages in Insite LMS. This ensures that you always know where which parts, components and tools can be found in a matter of seconds.

This means that materials can be found transparently and will no longer be lost.

Material inspections & completeness checks

Upon acceptance, the completeness and condition of the delivery is checked and documented directly via the app. First at the delivery level: Did all the boxes for the delivery arrive?

With Insite LMS, employees on the construction site can typically carry out structured material inspections when storing packages and package items and store the results transparently in the system. Were there over- or under-deliveries? Was there any transport damage?

Deviations and open points in the event of transport damage

If there are deviations, you can record them directly in the field in Insite LMS, link them to the relevant information (photos, delivery information) and assign them to the responsible processor.

plan.

row by

plan!

That is why global players in industrial construction rely on Insite LMS for managing material deliveries.

Increasing efficiency

With Insite LMS, the delivery of goods becomes easy to manage. Digital acceptance via an app makes incoming goods transparent and efficient.

Inventory management

The solution makes it possible to organize and manage storage locations and to define storage conditions. This ensures that materials can be found without tedious searching and that each material is stored correctly.

Transparency

Insite LMS increases project transparency and quality. The delivery status can be easily documented (e.g. with photos). Transport damage and NCRs can be recorded in the same system.

Conclusion

Using Insite LMS as your software for controlled goods receipt makes handling material deliveries on construction sites significantly easier. You know in advance when which materials will arrive, and with a simple QR code scan, you can access all relevant data digitally. Tasks like assigning storage locations or documenting damage can be handled directly via the app.

A new dimension in industrial construction

Insite LMS goes far beyond material deliveries and storage location management: it covers the full spectrum of requirements in industrial construction. The platform consists of numerous perfectly integrated modules, specifically developed for the needs of large-scale plant projects. This enables you to execute complex projects with maximum efficiency – without avoidable friction.

Hands-on guide:

How to digitize industrial construction

Making digital transformation easy: successful software adoption in industrial construction.